Do we need to subsidize ethanol production? Does it matter if we are subsidizing the input (i.e., corn)? This is not a rhetorical question.

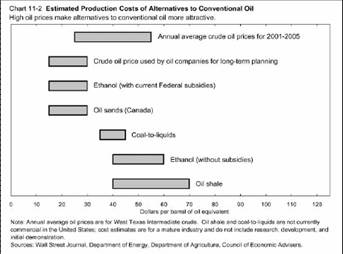

I found this chart in the 2006 Economic Report of the President quite interesting. It indicates that with WTI at between $40 and $60 per barrel, ethanol is profitable without subsidies.

Chart 11-2 from 2006 Economic Report of the President

The description is a little sketchy in the ERP, but it appears that the ethanol production costs are for mainly corn-derived ethanol, and for a “mature” industry. The latter I presume pertains to when economies of scale are exploited.

With oil prices now around $75 per barrel, and Dec. 2007 futures at about $77 (see INO), it would seem the case for subsidies and protection is severely diminished. However, EIA June forecasts are hovering about $60 until 2007q4, so the issue is in some doubt, given the uncertainty surrounding future prices and the fact that the industry probably has not fully attained the assumed economies of scale.

The rejoinder of course is that the government should not intervene in any case — let the magic of the marketplace work. I would argue that the price of oil does not fully reflect the costs associated with the costs of using oil (in specific terms, the marginal social cost does not equal the marginal social benefit). A related approach is to view the marginal private cost of producing of ethanol as exceeding the marginal social cost; hence subsidies might be appropriate even if capital markets were able to account for the eventual attainment of efficient scale of production.

A complication is the fact that the feedstock for ethanol is also subsidized. It is unclear whether the calculations in the chart incorporate this additional distortion, although it would appear not from the wording of the text. According to CBO (“Agriculture,” Budget Options, 2006), FY2005 mandatory expenditures in agriculture were estimated to be $25 billion. To quote: “Farm revenue-support programs, which extend through 2007 under the Farm Security and Rural Investment Act of 2002, account for most of the mandatory spending in function 350.” It’s unclear whether corn prices are higher or lower than the distortion-free counterfactual, given the price supports and subsidies (references anybody?). The weflare implications are also complicated, then. What looks, in a partial equilibrium context, like a good expenditure might look less desireable taking into account general equilibrium factors.

Technorati Tags: energy dependence, ethanol subsidies, and

oil prices

The fundamental problem with ethanol as a fuel substitute isn’t the monetary cost of production but rather the fundamental physics of how much usable energy is gained for how much expended in production; the EROEI of corn ethanol (energy returned for energy invested).

The best, non-partisan study to date has been done by the USFA (authors: Shapouri, Duffield, Wang). From the abstract:

Studies conducted since the late 1970s have estimated the net energy value (NEV)

of corn ethanol. However, variations in data and assumptions used among the

studies have resulted in a wide range of estimates. This study identifies the factors

causing this wide variation and develops a more consistent estimate. We conclude

that the NEV of corn ethanol has been rising over time due to technological

advances in ethanol conversion and increased efficiency in farm production. We

show that corn ethanol is energy efficient as indicated by an energy output:input

ratio of 1.34.

That figure rather unfavorably compares to the most costly domestic oil wells with a ratio 1:8.

While net energy positive, by comparison with every other source of alternative energy, corn ethanol is simply too inefficient for a sensible society to develop (Yes, the Brazilians are succesfully using ethanol but theirs is sugar cane based, with an estimated EROEI twice that of corn, and they are generally more frugal in their overall energy usage.

I see Brazil mentioned frequently as an example. And when in this country is anybody going to pay farm workers 5-10 dollars a day? So using Brazil as an example is bogus.

Two things to consider HM…

1) Increasingly the energy to distill ethanol & dry the by products comes from coal (co-situated co-generation of electricity & steam with the low pressure steam AFTER turbines used to distill & evaporate). This situation is especially true for the larger wet mills run by ADM, Cargill & others.

So in this respect the overall inputs & outputs in effect reduce corn-ethanol into a ‘synfuels process’… coal to liquid fuels via corn. The net energy isn’t a lot different but the ratio of ‘energy utility’ is far greater – useful electricity & liquid fuels from less useful coal.

When looked at like that the question becomes which makes more sense – fermentation to ethanol based liquid fuels or Fischer-Tropesch paths to liquid fuels. Although I originally studied as a chem engineer its been years ago and I have no idea which would be best. Maybe Dr Hamilton can walk across campus & get one of the wonks to crunch the numbers & enlighten us all.

2) Wet mill operations ‘fractionate’ corn into germ (oil & high protien feed), gluten (high protien feed), fiber (cattle feed) and starch. The starch process stream is processed into sweeteners, corn starch or ethanol. Considering how cheap sugar & corn syrup is starch almost becomes a by product with ethanol an excellent ‘value outlet’. Plus considering all the other valuable products from the corn process – can sugar doesn’t look so great in comparison. In that respect corn ethanol production makes a little more sense if the whole package is compared.

So in a wet mill besides not destroying the best food value of the corn they also have higher energy utility (ratio of easily useable energy produced from total energy input). So what’s the draw back? Capital cost – these plants are very complex & expensive.

BTW – My first job was as a chemical engineer at a wet mill. I was on the ground floor when our ethanol plant was built & started up. I have since moved on to other gigs.

Regardless I don’t see the scale up of corn based ethanol ever being sufficient to meet all our energy needs. It will always be a minor overall source of energy. An add on extra.

But other biomass options could be far more promising.

Do automobile engines have to be modified to run on ethanol?, Are we talking 95% ethanol /5% water, or a final distillation to 100%. Nobody talks about lubricating oil. Castor plants will have to be grown too.

nomial-

Most cars can run fine on 10-15% ethanol, which is readily available and is mandated in MN. Usually some modifications have to be done to run on the E-85 (85% ethanol) because it is far more corrosive than gasoline and will eat up regular fuel system parts. Some also say that things like piston rings and valve seals will not last as long with E-85, but as yet that theory is a little up in the air, I think.

The amount of oil to make lubricating oil, at least in motor vehicles, is a tiny fraction compared to the amount of gasoline used. A little over a gallon of motor oil lasts at least 3,000 miles in most cars and some say you can go up to 7,500 miles before changes.

Since farm subsidies are implemented to raise prices to some fraction of parity, increasing demand for corn should decrease the subsidies required with the gain going to the government. At some point the subsidy should disappear.

dryfly,

You made an excellent point about factoring energy utility as a consideration when evaluating various alternative energy sources. Certainly, until/if a predominately electrified transportation scenario comes about, the need for liquid fuels is going to an important issue.

A rough equation for ranking various energy sources might be something like this:

Energy returned on energy invested (structural energy utility) – monetary cost per btu achieved = Usefulness

(energy utility being a function)

The above is why among competing alternative fuels, ethanol and oil sands recovery has attracted the most attention.

With the requirement for oxygenated fuels and the prohibition of MBTE, that leaves only ethanol as a practical additive.

With the cost of fuel-grade ethanol soaring, you’ve got the gasoline “tax” you’ve always wanted. Even better that it is hidden! The downside is that the revenues go to ADM and corn farmers rather than the Treasury.

I’ll have to check this afternoon after work if the cost of ethanol has affected the price of my Friday martini.

Do automobile engines have to be modified to run on ethanol?, Are we talking 95% ethanol /5% water, or a final distillation to 100%.

Currently ethanol is blended with gasoline – something like 5% to 10% ethanol. In such cases the engines require little modification (just need to be sure the polymers in the engine don’t deteriorate).

E85 is an 85% ethanol blend similar to what they use in Brazil (I understand) and here the engine needs modification but there are designs that will utilize either E85 or gasoline.

100% ethanol requires substantial modification & is a dedicated fix… ie can run ethanol only.

As per water? Its a bad thing – the ethanol has to be VERY close to ‘200 proof’ or 100%. If there is much more than a fractional of a percentage of water upon addition of gasoline it can separate (stable three phase condition – two liquids & one vapor phase). The water rich phase is heaviest and goes t the bottom & would stall the engine like what happens in winter.

Therefore they have to ‘crack the azeotrope’ & produce 100% ‘neat’ ethanol. Not as hard as it sounds though – I used to do it.

Nobody talks about lubricating oil. Castor plants will have to be grown too.

Here’s where other coal or biomass processes come in. Fisher-Tropsch syn gas to liquid fuels is also an excellent way to make lubricating oils. Just requires additional catalytic reforming to get the molecular weight you want. These synthetic lubes while more expensive are actually quite superior.

Nothing holding us back but cost. None of these routes & feed stocks are as cheap as Saudi oil.

HM – electric vehicles are definitely the answer in urban settings & for ground mass transit. We’ll still need liquid fuels for aviation & rural long range transportation… but it can be done.

Its reasons like this that I don’t suggest eating cyanide over ‘peak oil’. A combination of electric vehicles, some efficient liquid fuels based vehicles & conservation (travel less – live smarter) and we do everything we want with far less oil.

We lack imagination more than we lack energy.

So the short answer is, We can get by on oil and synthetic oil from coal, until the oil runs out, by which time the coal to oil will take up the slack. It would be better to start the coal to oil plants now, so that by the time they are needed a best design, will have evolved.

Production subsidies for ethanol

The price of oil is now high enough that ethanol production should probably be self-sustaining, but another “approach is to view the marginal private cost of producing of ethanol as exceeding the marginal social cost; hence subsidies might be appropria…

Although at the moment corn based ethanol has a negative EROEI and is not cost efficient, I have to point out that the same can be said about people. We do not stop subsidizing them.

Therefore, the case for subsidy can be made for new processes that might lead to break throughs in EROEI from better processes, new enzymes, faster growing bio-mass, use of marginal land, plants that use less irrigation given falling water tables, depleted aquifiers, soil salination from irrigation, soil degradation and run-off of wastes into fresh water courses, etc. Peak fresh water & peak arable land.

As the USA (in this example) is under pressure to reduce farmgate subsidies then finding alternative markets is part of the solution in the near-term while developing long-term solutions to rural development, climate change and reliance on imported foreign oil (including Canada’s thank you very much!).

Also in the coal to liquids via ethanol and bio-diesel the distinction between stationary power source and transport fuels have to be made. Wind, solar, geo-thermal, coal, nuclear, tidal and let us say methane harvesting as a by-product of meat production, also can contribute to better EROEI for ethanol and bio-diesel as transport fuels, but obviously not before substantial investments in the infrastructure first.

Just some ideas about why sometimes subsidies are justified if the status quo leads inevitably to the geological conclusion that no matter what we do fossil fuels are in terminal decline in any case. May as well develop some alternatives even if they are less than perfect substitutes.